How a Factory Produce a Metal Display Rack

Factory Production Process of Iron/Steel/custom Metal Display Rack, how to customize a custom metal display

Metal display racks are essential fixtures in retail stores, homes, and various commercial settings due to their durability and aesthetic appeal. The manufacturing process involves several systematic steps to ensure quality and efficiency. Here’s an overview of how metal display stand are produced in a factory setting:

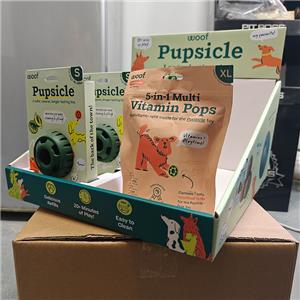

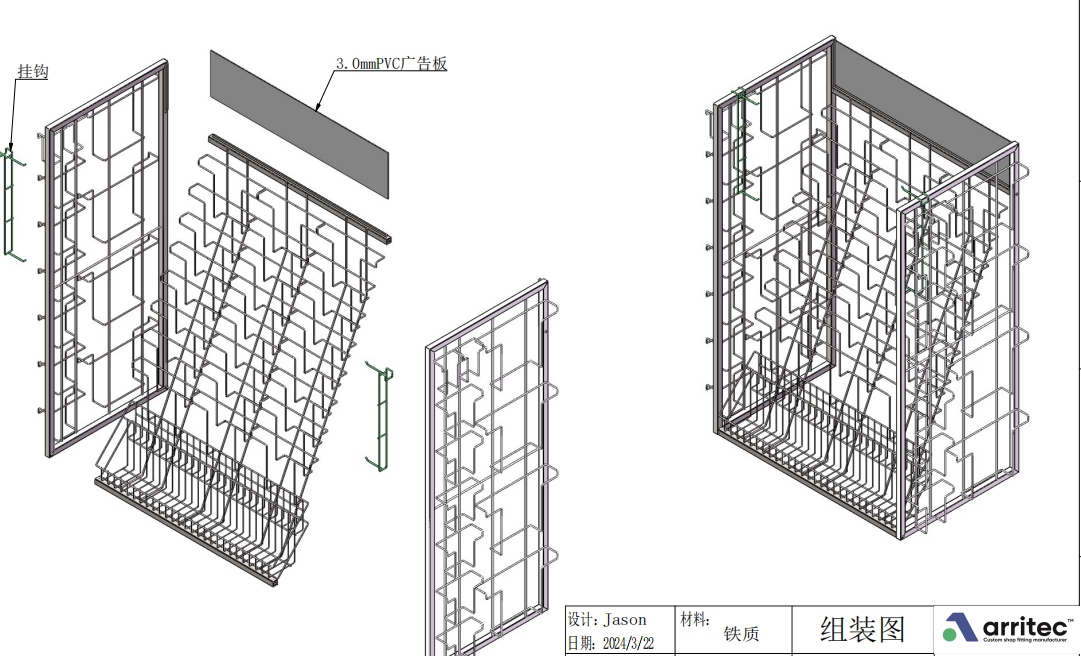

1. Design and Planning: The production process of metal display stand begins with detailed design and planning. Customer’s design or Idea for us like material, heavy duty loading, shelf arrangement, for which product on, even your budget. Those Factors are carefully evaluated during this phase.

2. Cutting and Shaping: After client confirmation of drawing, a prototype of metal display stand would be ready first. For example of a brochure postcard metal wire display stand . There are many pockets which need to be made by a auto 3D bending machine. so we call it metal wire display as well. The other parts will be cut according to the technical drawing.

4. Forming and Welding of metal wire display: The cut pieces are then formed and assembled into the frame and shelf structures of metal display stand. Skilled welders use welding machines to join the components together securely. Welding techniques vary depending on the design and structural requirements, with an emphasis on strength and stability.

5. Surface Treatment of metal display stand: After welding, the metal display rack undergo surface treatment processes to enhance their appearance and protect against corrosion. This may involve processes such as sandblasting, grinding, or applying protective coatings like powder coating or paint. Surface treatments not only improve aesthetics but also contribute to the longevity of the custom metal displays. We have our own powder coated line.

6. Quality Control and Packaging of metal hook display: Once the metal hook display parts treated, custom metal display rack are going into our package line, before that, all the elements of metal wire display need to be quality checking. Defective units are identified and rectified or rejected to maintain high production standards. Most of custom metal displays are disassembled. A piece of installation manual is required with metal hook display package.

7. Shipping and Customer Support of metal hook display: Upon passing quality control checks, the finished metal wire display stand are carefully packaged to prevent damage during transportation. LCL or FCL shipment by vessel or air. Customer support teams are available to address any queries or issues related to the metal hook display product, ensuring a smooth and satisfactory experience for end-users.